Robert Helleur

Memorial University of Newfoundland, Canada

Title: An integrated thermochemcial biorefinery for maritime forests

Biography

Biography: Robert Helleur

Abstract

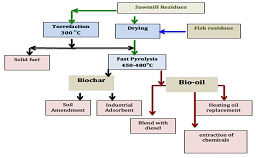

Biorefining is defined as the sustainable processing of biomass into marketable products and fuel. In the Canadian Maritimes waste biomass can be readily obtained from forestry and fishery sectors and municipalities (solid wastes). The integrated forest biorefinery consists of the addition of biorefining units to pulp and paper mills and local sawmills while maintaining the manufacturing of their core product. The biorefinery would provide a source of sustainable fuels and chemicals while increasing the value from wood residues and help diversify the sector. Processing woody biomass into fuels is the first step in biorefining, similar to the atmospheric distillation unit at an oil refinery or inlet separator at a gas plant. Over the last 4 years Memorial has partnered with BioFuelNet Canada, CSFI/DNR and Abritech (Quebec) in developing a comprehensive thermochemical research facility which includes a pilot scale fast pyrolysis unit (450-480oC;no O2). Pyrolysis converts biomass into liquid biofuel, biochar and useful chemical products. Given the average residues of a medium sawmill i.e., 3,500 tonnes/yr and the potential for other feedstocks (fishery) a number of integrated pathways are being considered (Figure 1). The bio-oil has the potential for a replacement or blend with heating oil for the sawmill and region. Depending on scale of the system there are opportunities to partner with other users such as pulp and Paper mills. The biochar product has a number of local markets including soil amendment and as an effective absorbent in the mining and oil and gas industry. Other integrated processes under development are torrefaction (300 oC; no O2), a pre-treatment leading to higher quality products.

Recent Publication:

Papari et al., Indust. Eng. Chem. Res., 56, 2017.

Whyte et al., Fuel processing Tech., 140, 2015.

Kan et al., RSER, 57, 2016.

Ferraro et al., Materials Sci. Eng. C, 33, 2013.

Zhang et al., Energy Conversion Management, 51, 2010.

Break:

Networking and Refreshments Break 11:05-11:25 @ Breakout Areas